The first time we buy the hose crimping machine, there are problems we are worry about, what do I need to do to receive the goods? When will I receive the goods? So I will have a brief introduction for the process of purchasing the hose crimping machines. (mainly for the DDP term).

First

Tell your supplier the voltage and phase you need and also your address you need the machine ship to. So that the supplier can check the price and freight and make the quotation for you.

Second

After agree the quotation, then make a payment. Generally, it is 100% prepaid. What we worry about is when make the payment and we didn’t got the machine. Please don’t worry, the supplier you can search with Google address will not deceive you.

Third

The supplier manufactures the machine. This period takes about half a month.

Fourth

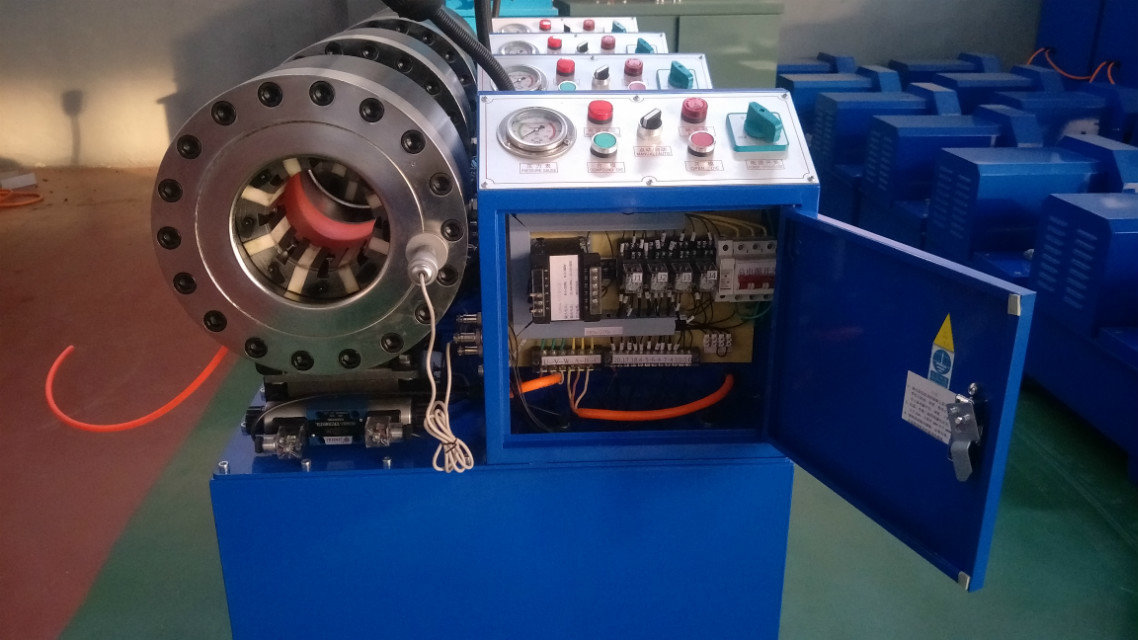

When the machine finished, the supplier will book the shipment space. In this period, you can ask your supplier for the production photos and packing photos of your machine. When the shipping order is released, the supplier will tell you the shipment date, the estimated arrival date, and the pick-up process.

Fifth

After the machine arrives at the destination port, it will be delivered to your address in about a week. Then you will receive your hose crimping machine.

After-sales problems.

If there are any problems when your received this machine, you can tell the supplier. They will solve it for you.